krishmrindia@gmail.com +91 7982189776

Sewage Treatment Plant

Sewage Treatment Plant

Description of Process: The treatment process shall comprise the following stages: Physical treatment : Coarse bar-screening Equalization tank : Flow equalization with air mixing Biological treatment : Activated Sludge Process Final sedimentation : Final settling tank Disinfectants : Chlorine Dosing/UV sterilizer Sludge disposal : Dewatering Process Description: The Contractor shall design the Sewage Treatment Plant to receive continuous sewage inflow within the plant room allocated on the site plan. The ease of maintenance and operation is of utmost importance in the design of Sewage Treatment Plant. Performance Criteria of the Plant: Raw sewage will be brought into the Sewage Treatment Plant. The Contractor shall receive sewage from this point to the treatment plant for treatment process. The treatment plant shall be designed to treat the following basic characteristic expected in the raw sewage.

Sewage Treatment Plant Based on ASP

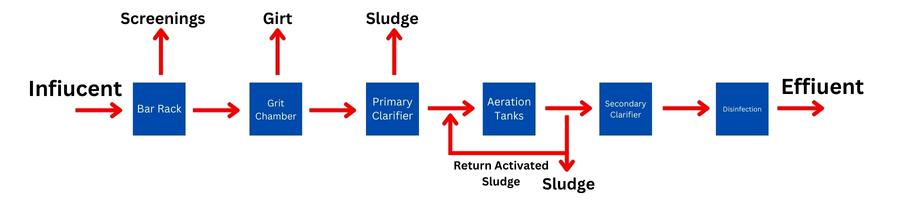

Biological Wastewater Treatment with Activated-Sludge Process The picture below shows a simplified flow diagram for biological processes used for wastewater treatment. The influent wastewater (e.g. municipal wastewater) goes through several stages in which different compound are removed out of the wastewater. Simplified flow diagram for a biological wastewater treatment with a activated-sludge process. In the Bar Rack coarse solids are removed, such as sticks, rags, and other debris in untreated wastewater by interception. By use of fine screening even floatable matter and algae are removed. In the Grit Chamber grit is removed consisting of sand, gravel, cinders, or other heavy solid materials that have subsiding velocities or specific gravities substantially greater than those of the organic putrescible solids in wastewater.

Sewage Treatment Plant Based on MBBR

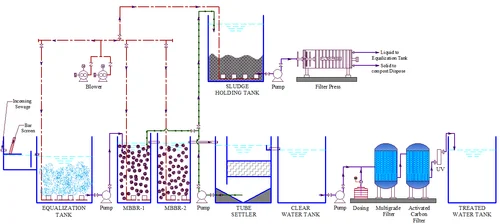

Moving Bed Biological Reactor KIW India provides clients Moving Bed Biological Reactor that primarily removes wastewater in three stages that are Primary Settlement, Aeration and Final Settlement. This robust treatment plant is simple in design and suitable for broad range of applications. This system can be supplied and installed with air blowers. Apart from this, minimum civil work is required

Flow Chart of Moving Bed Biological Reactor

Sewage Treatment Plant Based on MBR

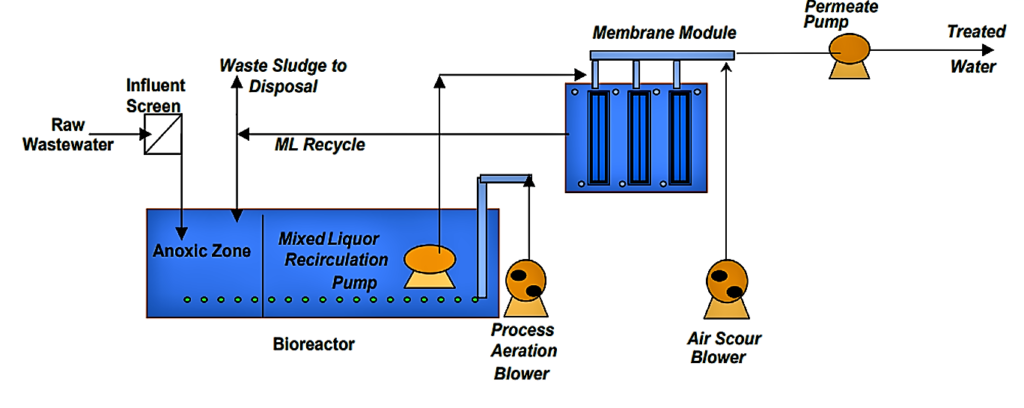

Modular Sewage Treatment Plant The Membrane BioReactor (MBR) is a state of the art pre-engineered sewage treatment system utilizing KIW India water treatment expertise with submerged membrane technology. The membrane separation process eliminates the conventional sedimentation tank and allows high volumetric loading, resulting in a smaller footprint. The MBR can produce high quality effluent with high BOD5 removal (about 98%), complete nitrification and partial de-nitrification and achieves virtually complete TSS removal. Submerged Flat Sheet Membrane Technology The MBR unit uses Toray flat sheet membranes immersed in the process tank in direct contact with the mixed liquor. Air injected from a manifold at the bottom of the membrane assembly helps to keep the membrane surfaces clean as well as supply oxygen for biological growth. MBR is equipped with a high level of automation, ensuring the plant’s simple operation and low maintenance cost. Higher efficiency Using membranes to separate sludge ensures higher quality treated water free from suspended solids. Membranes can retain activated sludge at high concentrations, resulting in more efficient BOD and nitrogen removal.

Flow Chart of Membrane Bio Reactor

Sewage Treatment Plant Based on SBR

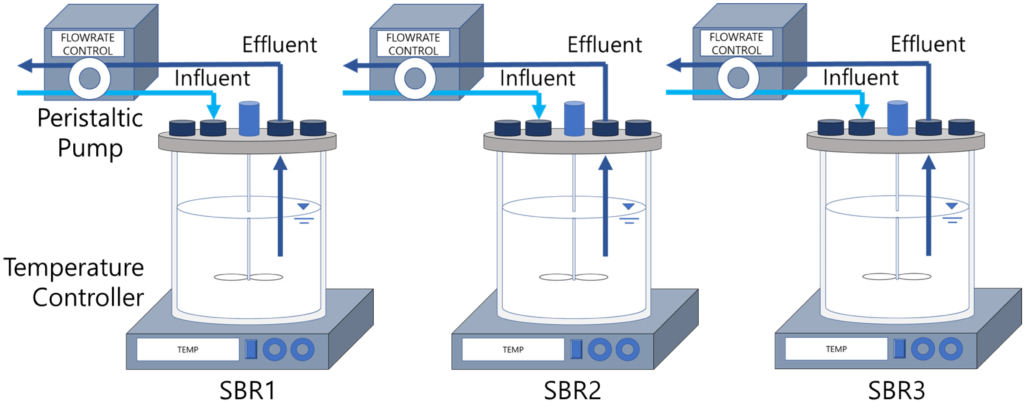

The Sequencing Batch Reactor (SBR) is an activated sludge process designed to operate under non-steady state conditions. An SBR operates in a true batch mode with aeration and sludge settlement both occurring in the same tank. The major differences between SBR and conventional continuous-flow, activated sludge system is that the SBR tank carries out the functions of equalization aeration and sedimentation in a time sequence rather than in the conventional space sequence of continuous-flow systems. In addition, the SBR system can be designed with the ability to treat a wide range of influent volumes whereas the continuous system is based upon a fixed influent flowrate. Thus, there is a degree of flexibility associated with working in a time rather than in a space sequence [1]. SBRs produce sludges with good settling properties providing the influent wastewater is admitted into the aeration in a controlled manner. Controls range from a simplified float and timer based system with a PLC to a PC based SCADA system with color graphics using either flow proportional aeration or dissolved oxygen controlled aeration to reduce aeration to reduce energy consumption and enhance the selective pressures for BOD, nutrient removal, and control of filaments [1]. An appropriately designed SBR process is a unique combination of equipment and software. Working with automated control reduces the number of operator skill and attention requirement.

Flow Chart of SBR

Up flow Anaerobic Sludge Blanket

Upflow Anaerobic Sludge Blanket Reactor (UASB) Up flow anaerobic sludge blanket technology also known as UASB reactor is a form of anaerobic digester which used in wastewater treatment. UASB reactor is a methane-producing digester, which uses an anaerobic process and forming a blanket of granular sludge and is processed by theanaerobic microorganisms.

Flow Chart of Up flow Anaerobic Sludge Blanket

Sewage Treatment Plant Based on SAFF

Submerged Aerated Fixed Films (SAFF) technology is a process used to reduce the organic loading of residential and commercial sewage / waste water, and in doing so will reduce the Biological Oxygen Demand (BOD) and a significant quantity of Suspended Solids (SS) which if otherwise untreated would contaminate river and sea outfalls, in other words it is used to substantially improve effluent discharge quality.

As with traditional sewage treatment, Submerged Aerated Fixed Films Technology too uses three stages of dealing with commercial and residential sewage / waste water.

Sewage Treatment Plant Based on Extended Aeration

Extended Aeration treatment system works by providing ideal conditions for aerobic bacteria and other micro-organisms; these micro-organisms then decompose the biological contaminants in the raw sewage. The treatment plant provides the proper environment, sufficient oxygen and other elements which allow the bacteria to consume the organic matter and to live and multiply within the treatment plant. In this way the aerobic bacteria and microbes decompose the sewage and waste to a stable form – odor and nuisance-free.