krishmrindia@gmail.com +91 7982189776

Clarification Systems

Clarifier

Our Clarifier is a crucial component of wastewater treatment, designed to efficiently separate solids from liquids. Using advanced settling technology, it removes suspended particles and impurities, producing clear, high-quality effluent. Essential for both primary and secondary treatment processes, our clarifier ensures optimal performance and compliance with environmental standards. It enhances overall system efficiency, reduces sludge volume, and supports sustainable water management practices. Trust our state-of-the-art clarifier for reliable and effective wastewater treatment solutions.

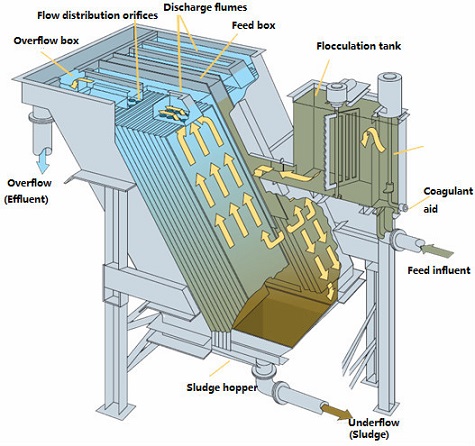

Lamella Plate Settler

Lamella Plate Settler for clarifying and thickening KIW India lamella principle uses several parallel inclined plates to maximize the available area for any available floor area. In this way, the size and cost of the gravity settler can be minimized by matching the thickening and clarifying requirements more closely. The two basic criteria for gravity settling equipment are good clarity of the overflow liquid and maximum density of the underflow solids discharge. The area needed to clarify a suspension is often greater than that needed for thickening. This means that in a cylindrical thickening tank, the lower section with rakes and drive mechanism can be oversized. Last years there has been an increased interest for using the KIW India IPS in the textile and steel industry.

Flow Chart of Inclined Tube Settler

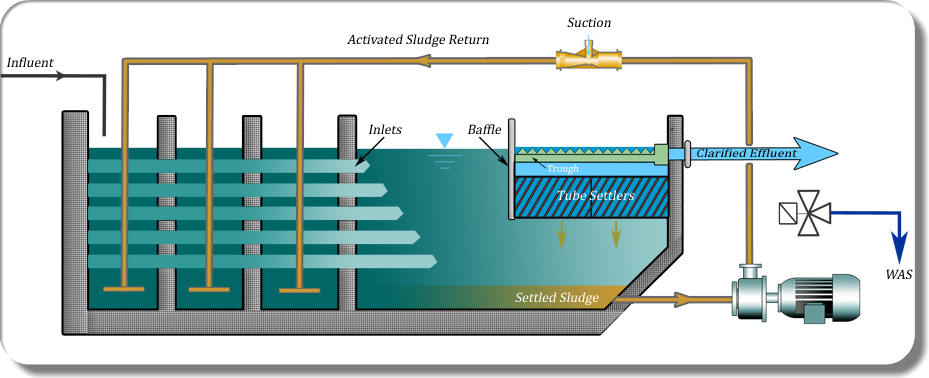

Tube Settler

Tube settlers increase the settling capacity of circular clarifiers and/or rectangular sedimentation basins by reducing the vertical distance a floc particle must settle before agglomerating to form larger particles. The settlers use multiple tubular channels sloped at an angle of 60° and adjacent to each other, which combine to form an increased effective settling area. This provides for a particle settling depth that is significantly less than the settling depth of a conventional clarifier, reducing settling times. Tube settlers capture the settleable fine floc that escapes the clarification zone beneath the tube settlers and allows the larger floc to travel to the tank bottom in a more settleable form. The settler’s channel collects solids into a compact mass which promotes the solids to slide down the tube Channel. Why KIW India Tube Settlers? Tube settlers offer an inexpensive method of upgrading existing water treatment plant clarifiers and sedimentation basins to improve performance.

Flow Chart of Tube Settler

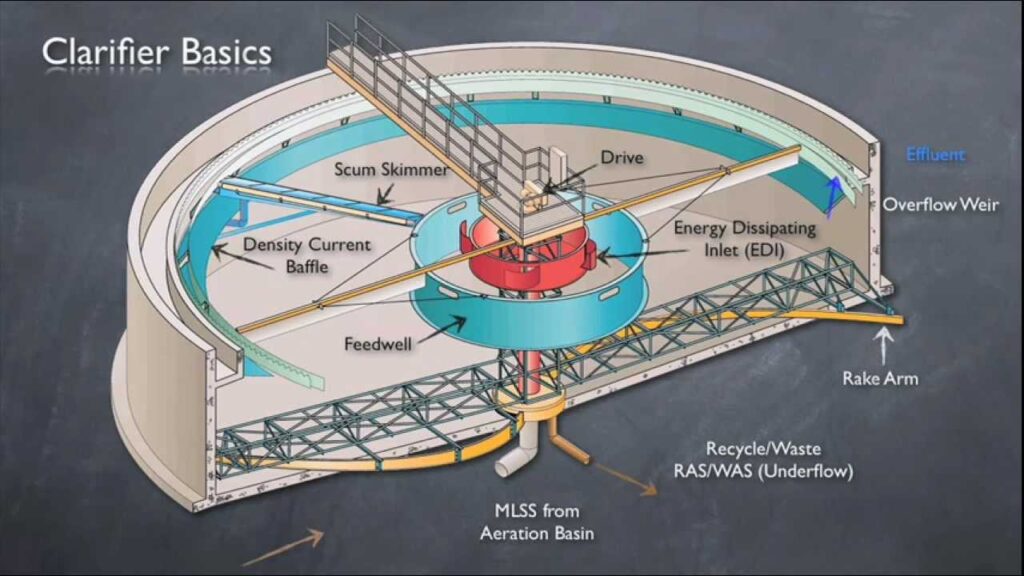

Circular Clarifier/ Thickener

KIW India ( Solid Contact Clarifier) is a true solids contact reactor which uses a propeller for internal solids recirculation and a variable settling area for solids separation. There are more than ten (10) design variations. Unit dependent on basin design (i.e. inlet location, mechanism support and flow rate). Process applications include surface water clarification, iron and manganese removal, cold lime softening and heavy metals precipitation. The units can be installed in round or square, steel or concrete basins. Multiple units are used for higher clarification flow rates. Water enters tangential to the base of the unit and spirals upward to the effluent collection trough at the top of the basin. Multiple units are used for higher flow rates..

Flow Chart of Circular Clarifier / Thickner

Category Of Clarifier

![Lamella Clarifier[96]](https://kiw-india.com/wp-content/uploads/2024/08/Lamella-Clarifier96.jpg)